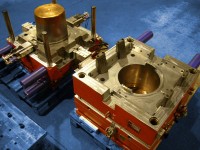

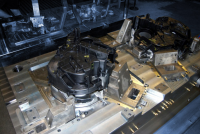

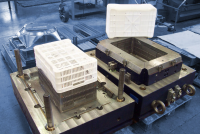

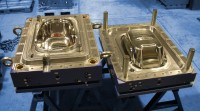

Over the past 10 years, technology has made giant steps, multiplying the offer of solutions for every type of problem. Our sector is no different and from a simple thermoplastic mould we have gone on to technologies such as: IML (in moulding labelling) - IMD (in moulding decoration) - double-triple injection - rotating moulds - sandwich equipment - co-moulding - plastic-plastic, rubber-plastic or steel-rubber-plastic and transfer moulds, complete machines that assemble other parts of the same component as well as carrying out traditional moulding.

The construction of moulds is MIP's core business along with design, and even if we were to write reams, we could never better describe the in-depth experience we have gained in more than 30 years' activity, during this period facing many obstacles which have always been overcome with skill and tenacity in continuous collaboration with our customers, who finally benefit from the equipment we build. We may also say that if we still exist and are doing the same job 30 years after, then something positive we have achieved...

Every year we plough back part of our resources into implementing the production department with the most modern machinery, 5-axis CNC, software of utmost performance and in the training of staff so we can give a prompt answer to so many problems.